The closed-circuit cooling tower is designed to cool water at the lowest possible cost in two ways, dry and wet. In the dry method, the environment to be cooled is cooled to ambient temperature, while in the wet method, the humidity conditions are manipulated to provide cooler air than the ambient temperature. In this system, cold air cools the environment and as a result, energy consumption is saved.

Cooling towers are often used in residential and commercial areas such as the roofs of hospitals or shopping malls because they work quietly thanks to their radial design.

closed circle cooling tower operation

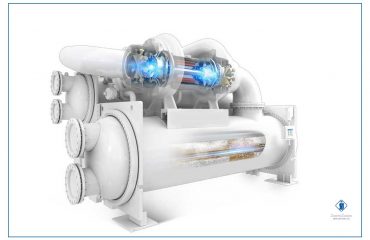

Closed-circuit cooling towers operate similarly to open-circuit cooling towers, except that the heat load to be passed through the process fluid (refrigerant) is transferred to the ambient air through the heat exchange coil. The coil works to separate the process fluid from the outside air, keeping it clean and free of any contamination in a closed loop. It creates two separate fluid circuits:

An external circuit in which water is sprayed around the coil and mixes with the outside air and an internal circuit in which the process fluid circulates inside the coil. During operation, heat is transferred from the internal circuit through the coil to the spray water and then transferred by evaporation of some water to the atmosphere.

The closed circle tower system consists of an open cooling tower with a separate heat exchanger package. The hot side of the heat exchanger also never comes into direct contact with air. This allows the heat exchanger, along with other indoor system benefits, to be protected from outside weather conditions. This closed system is much more durable than the external winding type closed circle cooling tower.

Advantages of closed circle cooling towers

Productivity of closed circle towers

If a program needs to generate full capacity throughout the year, it is important to maintain a clean and reliable cycle. Isolation of process fluid in a closed circle system prevents air pollution and other contaminants from entering the system. Maintaining optimal performance in an open circuit system requires regular maintenance to maintain similar performance. High-performance chillers and heat exchangers require clean process water to function properly, and even a small amount of contamination is significantly affected.

Cost of cooling tower

The cost of basic equipment of an open circuit system will be less than a closed circuit system of the same size because the open circuit system does not include intermediate heat exchanger components. However, the higher initial cost of a closed circle system will be recouped over many years of operation through the following savings:

- A cleaner process fluid leads to a cleaner internal surface and more efficient components in the system (eg chiller).

- Reduce system maintenance costs

- Reduce water treatment costs for steam equipment

- In winter, energy saving mode is available to save energy.

taking care

Because the process fluid of a closed circle system is completely isolated from the environment, routine maintenance is required only on the heat removal equipment itself. The need to shut down the system completely to clean the heat exchanger is significantly reduced if the components are not completely out of the ordinary. Circulating clean fluid into the process system also increases the life of other system components (condenser packages, compressors, etc.).

Maintenance and filtering

Maintaining the proper quality of process fluid in a system may involve several steps, such as chemical treatment, filtration equipment, and the addition of clean water. Closed-circuit cooling tower can offer the following advantages over open-circuit cooling tower:

- Less circulating water volume for purification

- The processing cycle requires minimal processing.

- Clean water will not be needed during dry operation.

Operational flexibility

closed circle towers enable the following operating modes that are not possible in open circuit towers:

- Cooling operation without the need for an interface heat exchanger: The chiller is closed.

- Dry function: Preserves water and refined chemicals to prevent frostbite and lint formation.

- Variable pumping: Condenser water circuit provides variable speed pumping conditions to save energy.

English

English  فارسی

فارسی