Cool air chiller is one of the most common types of chillers, especially for small and medium-sized commercial and office buildings. These chillers are usually installed outdoors, either on the ceiling or on a level surface or floor. This is because cool air chillers do not use a cooling tower and instead discharge their heat into the ambient air, which is why they need a large amount of fresh air to remove unwanted and unpleasant heat from the building.

The chiller generates cold water, which is pumped to all parts of the building and reaches the air distribution units or fan coils to dissipate unwanted heat from the building and transfer it to the cooled water cycle. The cooled water reaches the distribution units or fan coils at a temperature of about 6 degrees Celsius (42.8 degrees Fahrenheit) and over time, the heat exchanger inside the fan coils or units increases to a temperature of about 12 degrees Celsius (53.6 degrees Fahrenheit). Is leaving. Cool air then travels to the chiller to transfer its heat to the surrounding air before re-entering the cycle.

When this water returns to the cycle, it enters the evaporator, where it passes through the outer surface of the pipes containing the refrigerant. After this, the water leaves the other side while it has lost its heat. Refrigerant is the only liquid that passes through all parts of the chiller. The pressure, temperature and enthalpy of the refrigerant change as it passes through different parts of the device and dissipates unwanted heat from the evaporator cooled water.

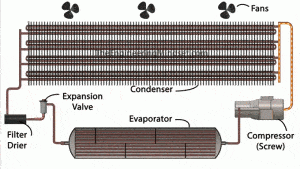

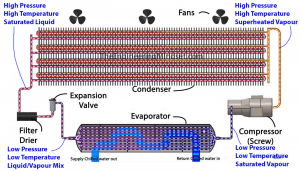

Cool air chiller has five main components:

- Compressors, which are usually screw or spiral, scroll or screw, and piston or impact or reciprocating.

- Condenser, a group of horizontal tubes containing hot refrigerant. These pipes are surrounded by a number of thin metal sheets on a vertical axis. These sheets help transfer heat from the pipes to the air that is blown from the top of the pipes and metal plates.

- Condenser fans. These fans draw air from the sides into the condenser coils and then force it out of the upper part and into the open space of the outside environment.

- Expansion valve, which expands the refrigerant before it enters the evaporator.

- An evaporator, where cooled water is produced, and the heat of cold return water that was previously cooled and now heated is extracted to be sent to the condenser.

How the refrigerant moves in the chiller:

The compressor is considered as the driving force for the refrigerant. The refrigerant first leaves the compressor with a gaseous state and high pressure and temperature and then enters the condenser.

When refrigerant enters the condenser, it passes through horizontal pipes and transfers its thermal energy to the air inside the ambient space, which is located on top of this part by the fans.

While the refrigerant is transferring its heat, it condenses and reaches the liquid phase. Over time, the refrigerant reaches a saturated liquid with high pressure and medium temperature and leaves the condenser.

The refrigerant will then enter the expansion valve. The expansion valve measures the refrigerant flow inside the system. The most basic and basic form of this device is the thermal expansion valve, which controls the refrigerant flow by measuring the temperature of the tube at the evaporator outlet and adjusts the flow rate to keep the temperature at the desired point.

The expansion valve traps the refrigerant and maintains high condenser pressure. Inside the expansion valve, a small hole allows a limited amount of refrigerant to pass through to continue the flow. By passing through this orifice, the refrigerant reaches the low pressure part of the expansion valve. This sudden drop in pressure allows the refrigerant to expand to change from a liquid phase to a gas / liquid phase. When this happens, the pressure and temperature of the refrigerant will decrease. A similar amount passes through the refrigerant and as a result there is more room to expand and fill this gap.

The refrigerant then enters the evaporator and passes through a series of horizontal tubes surrounded by cold water and flowing in opposite directions. Over time, the refrigerant absorbs the unwanted heat from the return of cold water, leaving the evaporator at low pressure and temperature and in the state of saturated gas. The cooled water will also give off its heat to the refrigerant and leave the environment at a temperature of about 6 degrees Celsius (42.6 degrees Fahrenheit).

Sources:

English

English  فارسی

فارسی