What is a cooling tower and what is its function?

The cooling tower is the part of the air conditioning system that prepares the used water for operation. In this way, the tower is located in a part of the air conditioning activity cycle for domestic or industrial activities, absorbs the water that has reached high temperature during the cycle path and lowers the water temperature in different ways. In fact, the cooling tower removes heat from the water and transfers it to the ambient air. After the temperature drops, the water leaves the cooling tower and returns to the activity cycle. In this way, the wastewater does not need to be discarded but is placed in a similar recycling cycle. Cooling towers are produced in different dimensions and with different raw materials for different uses. One of these types of towers is the home cooling tower.

What is the consumption and application of a home cooling tower?

Home cooling towers are not used in the form and scale of industrial cooling towers but are commonly used for cold water chillers.

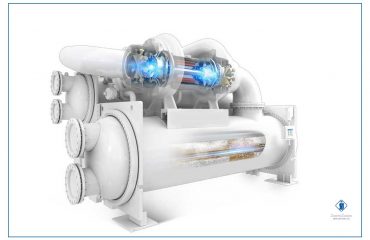

Chillers are also one of the air conditioning systems that have different types and in different ways based on thermodynamic processes and with the help of phase change of a refrigerant, lower the water temperature to return to the activity cycle. But for chillers, two general types are defined: cold water chiller and cold air chiller.

A cool air chiller is a relatively independent ventilation system that does its job without any auxiliary tools. In the condenser part of this chiller, nothing but the surrounding air is used for cooling. Conversely, in cold water chillers, there must be a cooling tower to cool the condenser part of the chiller, because the condenser of this chiller works with water. This cooling tower is responsible for cooling and reducing the water temperature inside the chiller. In fact, in these chillers, in addition to the circuit between the various components, such as the condenser and the rest of the components, another cycle takes place between the condenser and the cooling tower, independent of the main circuit. In this way, the cold water chiller can not operate without a cooling tower. Meanwhile, in-home air conditioning systems and cold water chillers, instead of high-powered and large cooling towers with high dimensions, a home cooling tower with less capacity is used in proportion to consumption.

Household cooling tower material

Cooling towers use different materials such as concrete, wood, galvanized and fibreglass. Fibreglass or Fiber Resistance Polymer is a composite material that is made of glass fibres and polymer resins and adhesives. Fibreglass option is used to build home cooling towers because:

- It is light in weight and light in weight

- It is easy to transport

- It has a great variety of colours and designs

- Sufficiently resistant to destructive environmental factors

- It does not oxidize

- It does not pass the heat of the sun

- It has a long life

- It is affordable

Factors influencing the selection of a suitable home cooling tower

Home cooling towers are manufactured for home use, but there are design criteria that ultimately lead to the production of different types of cooling towers. Each of these criteria makes a home cooling tower more suitable for a particular area with a specific climate. Thus, before preparing a home tower that meets the needs of consumers, the following should be considered:

Humid temperature and dry temperature of the environment, which is determined by the meteorological stations of each region and is a basic parameter for the design of cooling towers. The basis of this parameter in the design of the cooling tower is the maximum or maximum humid temperature.

- Overall humidity of the environment

- Above sea level

- Inlet water temperature

- Outlet water temperature

- Inlet water flow to the cooling tower

- Water hardness

- The amount of dust and soil in the air of the region

Variety in choosing a home cooling tower for consumers

Variety of appearance:

Home cooling towers are available in two types, cubic and conical. Conical and round towers are more common for home use and are less expensive. On the other hand, if there is a defect in the conical cooling towers, such as component failure or sediment, the entire tower body must be opened. These sediments at the bottom of the tower prevent heat transfer from the water to the air and affect the useful performance of the tower.

But cubic towers are easier to repair and take less time to repair.

Variety of performance:

In terms of tower circuit, three types are defined for it: open circuit closed circuit and hybrid.

Open-circuit cooling towers operate on the basis of direct contact between the weather and evaporation. In this way, water is first directed to the top of the tower by a pump and then sprayed into it through the nozzles at the top of the tower. Then the air at the bottom of the tower is drawn upwards, the air is in contact with each other and part of the water evaporates. Because the evaporation process is an endothermic process, the water temperature decreases.

CCTV cooling towers, however, use coils inside and do not rely on direct weather contact. Since water does not come into direct contact with the air in these towers, the possibility of dust and impurities entering the tower is reduced. For this reason, maintenance of these towers is easier and less expensive.

The hybrid type is also a combination of open and closed circuit towers.

Variation of airflow in cooling towers:

Inductive and forced mechanical current, which can be in two types of cross-flow or cross flow or counter flow or opposite flow. These currents are generated by the impellers used in the tower and take on a forced or inductive name depending on whether they are installed at the beginning or end of the tower.

Benefits of the home cooling tower:

- Easy and fast assembly

- Resistant to corrosion and environmental conditions and wind and UV rays

- Easy and low maintenance

- Low consumption

- Do not produce noise pollution

- Low volume and low placement

English

English  فارسی

فارسی