Actions to increase the efficiency of chiller systems:

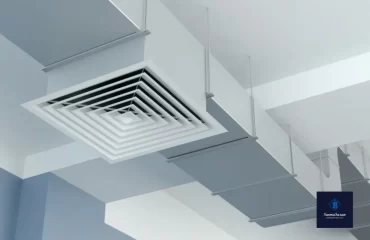

In the first part of the article, a comprehensive guide to different types of chillers, we explained how a chiller works and what categories it has. We are now reviewing methods and solutions to increase the efficiency of chillers. A significant portion of your construction bills are related to chiller costs. What can be done to save energy and at the same time get the most out of the chiller? Let’s look at a few possibilities.

Continuous and current maintenance

Chiller systems will perform better if maintained properly and properly. Most organizations have realized the value of this issue and have taken steps to address this as part of their day-to-day management practices. Some of the best practices for chillers include:

Handling and cleaning condenser coils: Heat transfer has a great impact on chillers and is essential for their efficient operation. Checking the clogging and free passage of air through the condenser coils is one of the things that should be done in daily maintenance and care.

Maintain the right amount of refrigerant: The chiller cooling coefficient depends on the proper level of refrigerant in the system. Maintaining the amount of refrigerant charge can completely affect energy efficiency and reduce costs by 5 to 10 percent.

Condenser water conservation: The condenser water cycle connected to the cooling towers must maintain the proper water flow as designed for it. Any waste and particles such as sand, abrasives and contaminants can affect the condenser water flow and the effective performance of the chiller.

Predictive repairs

Artificial intelligence (AI) is still evolving in every scientific field. Machines such as chillers can take advantage of artificial intelligence algorithms because they can detect the possibility of failure before it occurs. Predictive repairs use the collection and analysis of chiller operating information to determine when repairs are needed to prevent serious and harmful damage. Because chillers are at the heart of modern air conditioning systems, predicting fatal breakdowns that can cause serious malfunctions can save on emergency repair costs and job-related costs. The vital role of the chiller dictates that its operation be closely monitored. In this regard, data analysis and artificial intelligence can minimize device downtime and maximize device efficiency.

The Internet of Things (IoT) provides a data collection tool that can enable artificial intelligence applications such as predictive fixes. In fact, the future of air conditioning will lead to artificial intelligence and the Internet of Things. The Internet of Things enables the simultaneous collection of data from a chiller so that it can continuously analyze its performance. This information will go far beyond the information obtained through visual observation. The Internet of Things allows building engineers to view critical information at the same time, thus monitoring the actual conditions of operation.

Optimization of chillers

Chillers act as part of complex air conditioning systems. Coldwater chillers are more complicated due to their connection to the cooling tower. In this way, the overall performance evaluation of the chiller assembly includes the analysis of the compressor power consumption, pumps, cooling tower fans and other items to measure the overall efficiency by criteria in kilowatts per ton.

The overall optimization of the chiller assembly must be done comprehensively. There are several configurations focusing on optimal cold water adjustment points, chiller and equilibrium sequences, peak demand management, cooling tower water management, and others that are only applicable if operational data is available. The IoT, meanwhile, can provide tools for such optimizations. This is done by providing direct monitoring of the power consumption of each chiller component, or the reciprocating temperature of the water between the chiller and the cooling tower, the intensity of the water flow in the condenser cycle, and more. IoT is widely used to facilitate the proper optimization of the air conditioning system.

Conclusion:

The practical efficiency of the chiller will have a significant impact on your building costs. From the point of view of the structural manager, continuous maintenance of the chiller minimizes costs, but predictive monitoring and optimization of the chiller are also important while requiring direct access to operational information. In the meantime, the Internet of Things has opened the door to new forms of chiller efficiency.

English

English  فارسی

فارسی