Although automatic cooling towers are as productive and painless as possible, they rarely require a little care and attention. In this article, we will talk about the common problems of cooling towers and how to maintain them properly.

Industries with cooling towers need to record and control a variety of common water transfer problems. These common cooling tower problems cause the cooling tower capacity to be reduced by the amount and percentage of this capacity.

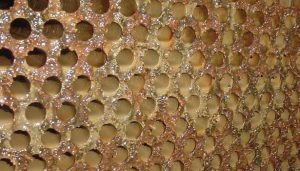

The problem of accumulation or accumulation of minerals in the cooling tower

Accumulation or scale of minerals (scale) is one of the common problems in the work of automatic cooling towers. Accumulation is often caused by the accumulation of mineral compounds in the water, such as calcium phosphate, magnesium silicate, and iron oxide. Heat transfer performance is reduced because the accumulation affects the main part of the cooling tower. If the accumulation is ignored, it can lead to huge energy costs for the operation of the cooling tower and may also require sealing and overhaul of the cooling system.

Mineral accumulation solution

The best way to prevent scale accumulation is to frequently clean the towers and reduce the volume of mineral accumulation.

Corrosion and erosion

Over time, water corrodes and erodes almost any substance known to mankind, and when corroded in automatic cooling towers, water is not the most important factor. While it can be assured that water is a device that provides the conditions for corrosive agents, the agents themselves are more serious than the effects of water. Many automatic cooling towers become sensitive and vulnerable to industrial chemicals during their lifetime. Corrosion can be a significant concern because it can minimize the operation and output of the tower, increase energy costs, and in worse conditions cause damage or damage to the equipment inside the tower.

Erosion and corrosion solution in the cooling tower

The proposed solution to reduce corrosion is frequent cleaning of towers. In addition, selecting cooling tower elements and chemicals that are usually corrosion-resistant, such as fibre-reinforced plastic, is a great way to overcome the problem of corrosion.

Sedimentation problem in the cooling tower

Sedimentation is the process by which the water in a cooling tower solidifies. Just as many cooling towers filter soil, dust, and biochemical components from the air, so does water. If left unchecked, unfiltered water can cause sediment in the tower, reducing productivity and increasing energy consumption.

The solution to deal with sediment in the cooling tower

To help overcome the amount of sediment that occurs, it is essential to use an appropriate and efficient filtration as well as to develop a chemical method to remove contaminants from the water.

microorganisms

While early problems were often identified with chemicals in the water of cooling towers, microorganisms are only blamed on the water itself. The cooling tower acts as an unwanted but suitable place for biological growth like bacteria. These pollutants can not be considered safe for people, just as they are harmful to the efficiency of cooling towers. The worst thing about these pollutants is that even very small volumes of them can dramatically reduce the thermal reaction.

The solution to reducing microorganisms in cooling towers

To prevent the growth of microorganisms in an automatic cooling tower, it is necessary to clean the cooling tower often with an antimicrobial cleaner.

Water treatment solutions in cooling towers

- Make sure your cooling tower is always optimized for microorganisms or biofilms. It is very obvious and very expensive to maintain, clean and wash.

- Get your peroxide regularly, store it in the shade, and make sure you ask about it at every run.

- Do inspections to clear up any doubts about changes to the cooling tower. You can get help from laboratories and experts in this field.

- Regular monitoring is the only method that is effective and practical at the peak of accumulation, corrosion and biological growth of the cooling tower. Monitor regularly!

- Joint water treatment of the chiller and cooling tower system, which includes cleaning the entire water and heat transfer system, is a good way to maintain the proper operation of the heating and air conditioning system (HVAC).

English

English  فارسی

فارسی