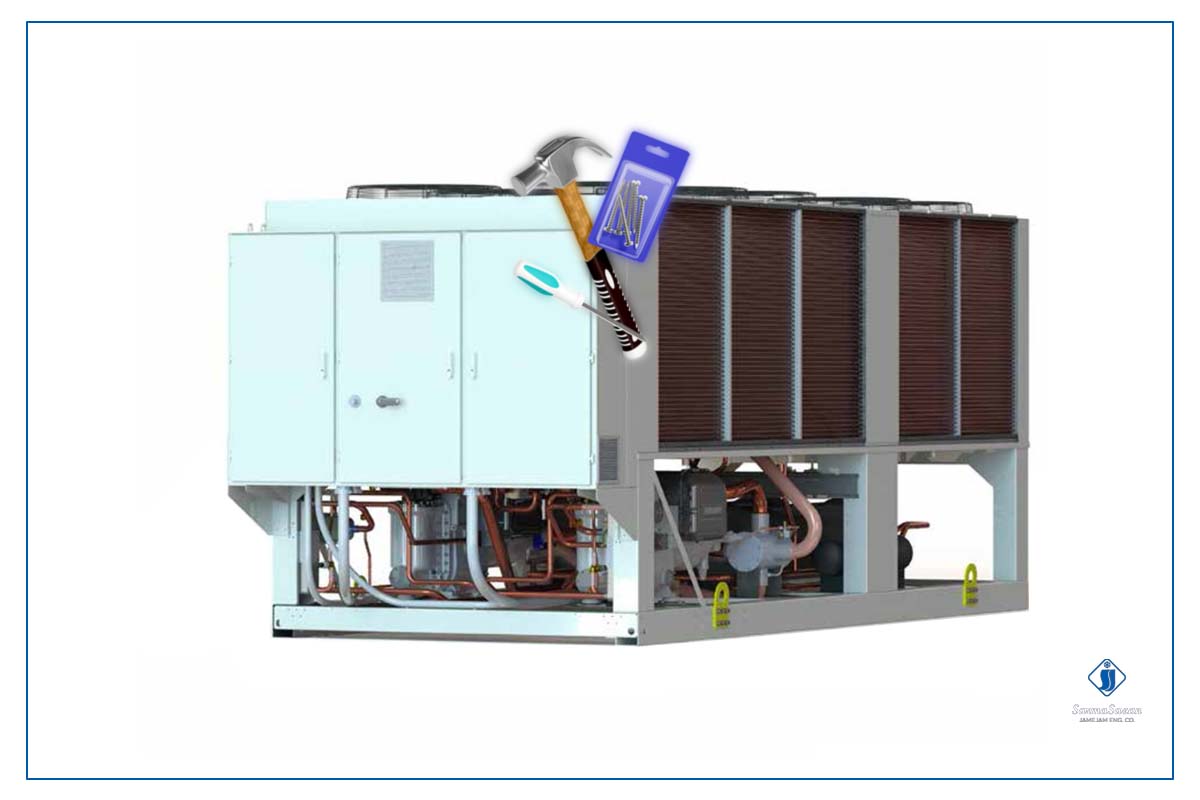

No matter how extensive and detailed your business or production process is; Shutting down and malfunctioning a device such as a chiller can be incredibly disruptive and costly and can even cause problems in meeting customer needs. Chiller and system maintenance is critical to reducing the risk of failure and extending the life of your equipment. By doing this, you can also make sure that you do everything you can to maintain your executive performance.

The following is a checklist of chiller maintenance:

- Provide you with daily principles for running a chiller

- Inform you about the best ways to maintain the chiller

- Advise you on what to look for when controlling the refrigerant flow of your equipment if you are working in the field.

- Allows you to act scientifically during preventive maintenance and care

Basic principles of chiller maintenance

Much like what you do with your car, daily maintenance and control of the chiller can prevent damage and breakdowns. Daily control of chiller operation takes less than two minutes, while it can make a significant difference in chiller performance, allowing you to prevent damage to the chiller instead of repairing it.

On a daily basis, you should check for any unusual movements, vibrations, or sounds and find the cause. Eye examinations should also be performed. Check for debris and debris around the chiller. Or loose chiller components such as thermal insulation are damaged and abandoned. Be sure to check for leaks.

If your chiller shows codes and signs of negative performance, it’s time to call a specialist. Do not rely solely on visual inspection to keep the chiller running. If left unchecked, it will almost certainly damage your chiller.

Do not put all these reviews on one person and do not make one person the sole representative of this work. Since these problems can quickly become a serious problem, keep in mind a printed daily report that lets all employees know if all equipment is being monitored on a daily basis. Also, teach them to do the controls themselves if they do not. You should have time to check your equipment either weekly or monthly. With careful planning, you will be able to tailor it to your executive plan. Remember that a chiller failure on the app is better than a predictable one, as you will be better prepared for it.

Chiller maintenance checklist

As much as we want technology to work at its most efficiently at all times, erosion and depreciation can lead to malfunctions. If you use chillers for your air conditioning system, getting to know the steps of preparing and maintaining chillers can be useful for you.

When it comes to chiller maintenance, we need to know how chillers work. Here are some tips to help make your chiller work better:

- Review and control daily performance reports

A daily performance report provides information that by the nature of its support; can help identify problems and fix chiller inefficiencies faster. Details in this report should include flow rate, operating temperature and other basic information. Having such a detailed report only takes a few minutes a day, but it can be the key you need when a problem arises.

- Regular use of water purifier

There are different types of chillers that are used in different conditions, but the most common are cold water chillers. To prevent sediment, corrosion and algae accumulation, this water must be constantly treated in a chiller and chemicals can be used for this purpose. The filters should also be cleaned every three months to prevent contamination.

- Quick stain treatment

Checking for stains and leaks should be the next item on your checklist. Contact a specialist if you encounter a stain. You should also check for locks, hinges, screws, and existing enclosures and boxes to prevent leaks.

Small stains on your chiller can lead to more serious problems. Unwanted moisture can accelerate the work of corrosive acids. In addition, moisture can rust parts of the chiller and impair its proper operation. Carefully inspect your chiller at least once every three months for stains.

- Cleaning the system pipes and their interior

The overall performance of the system depends on the efficient heat transfer between the tubes between the evaporator and the condenser. Keeping these pipes clean will keep your chiller running smoothly. To do this, you can use both chemicals and pens to remove sediment and algae.

It is best to open the side surfaces of the chiller for daily control. In this way, in addition to daily control, you should check that no dirt and dust enters the system.

- A regular check of oil and refrigerant

Regular control of the amount of oil and refrigerant in your system will prevent many complex problems. Continuous refrigerant monitoring can identify issues related to the purity of the refrigerant. Oil control also reveals hidden system problems, such as problems with compressor wear or excessive moisture in the oil.

From a safety point of view, it is important to disconnect the chiller from the electronic power source before continuing the tests. Once the chiller is safe, it is time to check the connections inside to make sure they are all secure or tightened if necessary.

A separate inspection of parts for chiller maintenance

Chiller compressor:

The compressor operates at different pressures, such as a pump, to move the refrigerant along the system, moving the liquid refrigerant through the system. Here are some key points to keep in mind when checking a compressor, or discussing them with a specialist:

- Suction temperature and pressure

- Discharge temperature and pressure

- Oil level and pressure

- Voltage and current levels, only if safe

Chiller evaporator:

The next piece to check is the chiller evaporator. The part whose job it is to capture the heat of the building or the heat resulting from the activity. Here are some key pointers in moving your controller forward, depending on the type of chiller you use:

- Temperature and pressure of air or inlet fluid

- Temperature and pressure of air or outlet fluid

- Inlet and outlet refrigerant temperatures

- Insulation conditions

Chiller condenser:

The last of the three components that should be on your checklist is the condenser, which removes the heat transferred from the compressor to the refrigerant. Similar to the evaporator, there are two types of condensers depending on the chiller, air cooler or water cooler, which can make minor changes to your reviews. The main points in checking the condenser include the following:

- The temperature of the air taken and evacuated

- Inlet and outlet refrigerant temperatures

- Sound and vibration of motor fans

- Condenser oil conditions

Finally, when facing a system failure or malfunction, try this common chiller solution:

If your pump is malfunctioning, check that all valves are open. Then check for deposits or debris that may have entered the pump. If everything looks clean, check that the pressure is moderate. If all goes well in this area, there is probably a problem with the internal components of the pump that requires a specialist.

English

English  فارسی

فارسی